RAPID

两个Items放在一个Container上

Simulation时,需要使用相机+Flow。可以在Pick程序的GetItmTgt程序前,先使用NextItmTgtType获取下一个Place的Container的第一个Item类型,然后使用该Container中的Item类型,指定GetItmTgt所需要获取的对应的Item,这样可以确保Item和Container中的Item一一对应,而不至于无序放置。

PROC Pick(num Index)

VAR num PlaceType;

VAR num PickType;

IF Index>0 THEN

WObjPick:=ItmSrcData{Index}.Wobj;

NextItmTgtType ItmSrcData{PlaceWorkArea{1}}.ItemSource,PlaceType;

TEST PlaceType

CASE 0:

PickType:=0;

CASE 2:

PickType:=2;

ENDTEST

GetItmTgt ItmSrcData{Index}.ItemSource,PickTarget\ItemType:=PickType;

!GetItmTgt ItmSrcData{Index}.ItemSource,PickTarget;

TriggL\Conc,RelTool(PickTarget.RobTgt,0,0,-ItmSrcData{Index}.OffsZ),MaxSpeed,ItmSrcData{Index}.VacuumAct1,z20,PickAct1\WObj:=WObjPick;

TriggL\Conc,PickTarget.RobTgt,LowSpeed,ItmSrcData{Index}.SimAttach1,z5\Inpos:=ItmSrcData{Index}.TrackPoint,PickAct1\WObj:=WObjPick;

GripLoad ItemLoad;

TriggL RelTool(PickTarget.RobTgt,0,0,-ItmSrcData{Index}.OffsZ),LowSpeed,ItmSrcData{Index}.Ack,z20,PickAct1\WObj:=WObjPick;

ELSE

ErrWrite "Missing item distribution","Cannot pick because no item distribution contains current work area."\RL2:="Please check configuration";

SafeStop;

ENDIF

ENDPROC

WalkTheData

该程序在ppaBase.sys系统模块中定义,运行该程序会在”HOME:\TheData.log”文件中记录当前的Conveyor WorkAreas (NonCnvWOData{MaxNoSources}) 和Indexed WorkAreas (ItmSrcData{MaxNoSources}) 值。通常建议把该指令写在如下PickPlace函数的While循环前面。

PROC PickPlace()

ConfL\Off;

IF RestartOK=FALSE THEN

SystemStopAction\Halt;

RAISE PPA_RESTART;

ENDIF

MoveL SafePos,VeryLowSpeed,fine,Gripper\WObj:=wobj0;

SetGO goVacBlow1,0;

ResetAx4 ROB_ID;

NotifyRunning;

IF (FirstTime=TRUE) THEN

WaitTime 1;

FOR i FROM 1 TO MaxNoSources DO

IF (ItmSrcData{i}.Used) THEN

WaitTime 0.2;

QStartItmSrc ItmSrcData{i}.ItemSource;

ENDIF

ENDFOR

EnumerateWorkAreas;

InitTriggs;

InitPickTune;

PickRateInit;

FirstTime:=FALSE;

WaitTime 0.2;

ENDIF

WalkTheData;

WHILE TRUE DO

IF (StopProcess=TRUE) THEN

StopProcess:=FALSE;

SafeStop;

ENDIF

PickPlaceSeq;

IncrPicks;

IF (CheckAx4Rev()=FALSE) THEN

MoveL SafePos,MaxSpeed,fine,Gripper\WObj:=wobj0;

ResetAx4 ROB_ID;

ENDIF

ENDWHILE

ERROR

TEST ERRNO

CASE PPA_RESTART:

RAISE ;

ENDTEST

ENDPROC

ItmSrcData

Index: 1

Used: TRUE

ItmSrc Name: ItmSrcCnv1

ItmSrc Id: 28

ItmSrcType: 1

ufmec: CNV1

VacActDelay: 0.02

VacRevDelay: 0.02

VacOffDelay: -0.02

TunePos x: 0

TunePos y: 0

TunePos z: 0

Followtime: 0.035

OffsZ: 30

Index: 2

Used: TRUE

ItmSrc Name: ItmSrcCnv2

ItmSrc Id: 27

ItmSrcType: 2

ufmec: CNV2

VacActDelay: 0.02

VacRevDelay: 0.02

VacOffDelay: -0.02

TunePos x: 0

TunePos y: 0

TunePos z: 0

Followtime: 0.035

OffsZ: 30

NonCnvWOData

Index: 1

Used: FALSE

Name: IdxWobj1

uframe.trans.x: 0

uframe.trans.y: 0

uframe.trans.z: 0

Index: 2

Used: FALSE

Name: IdxWobj2

uframe.trans.x: 0

uframe.trans.y: 0

uframe.trans.z: 0

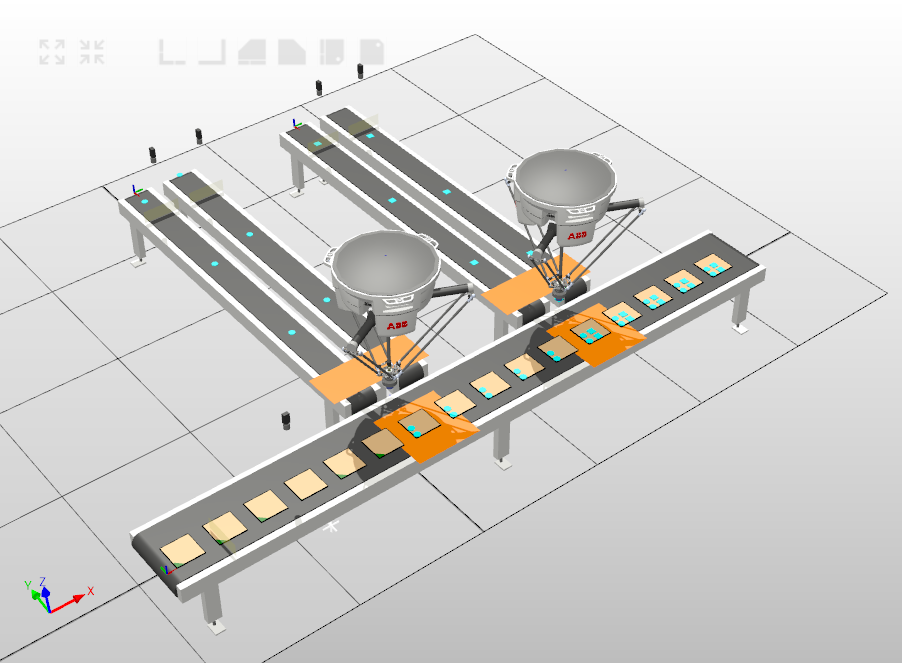

多个Pick或Place的WorkArea

简单的站,一般都只有一个PickArea和一个PlaceArea,但是实际的站可能会有多个WorkArea。当一个机器人有多个Pick或者Place的WorkArea时,需要修改PickPlaceSeq函数,才能让机器人去Pick或Place其它WorkArea中的item。如下代码所示,该站中有两个Pick WorkArea,一个Place WorkArea,这个站的作用是从两个传送带上Pick物品,然后放到第三条传送带上。如果不修改程序,那么永远只会抓取第一个传送带的item然后放置到第三条传送带上,第二条传送带的workarea由于工件坐标系存储在PickWorkArea{2}中,没有被调用,所以永远不会被抓取。

PROC PickPlaceSeq()

Pick PickWorkArea{1};

!Pick PickWorkArea{2};

Place PlaceWorkArea{1};

!Place PlaceWorkArea{2};

Pick PickWorkArea{2};

Place PlaceWorkArea{1};

ENDPROC

使用缓冲区Buffer

当传送带速度不是恒定是,比如Pick的传送带在某一时间内很快,虽然机器人可以正常抓取,但是由于Place传送带的Container来不及供应,导致机器人无处放置Item,此时可以设置一个缓冲区Buffer,让机器人先暂存在Buffer中。当过一段时间,Pick的传送带速度变慢了,此时Place的传送带的Container空出来了,虽然机器人可以正常放置,但因为没有item,导致机器人等待item,此时如果buffer中有数据,就可以从buffer中拾取之前放置的缓存item,然后放置在container中,提供整体生产效率。使用缓存不能使用Start/Stop功能,否则传送带可能会停下来,导致一直取不到item,陷入死循环。

判断是否启用buffer

是否启用buffer包含三种状态:

- Picked:=1,pick传送带有item,Place传送带有container,此时正常抓放。

- Picked:=2,Pick传送带有item,place传送带没有container,buffer中有item,此时机器人把item抓放到buffer中。

- Picked:=3,Pick传送带没有item,Place传送带有Container,buffer中缺item,此时机器人从buffer中拾取item放到contrainer中。

下面程序会先判断pick传送带中是否有item,如果有,就获取pick传送带的item type,如果该type的item有container可以放置,就设置Picked为1,如果没有,就判断该type的item在对应的buffer中有没有放满,如果没满就设置Picked为3,如果满了就啥也不干,可以重新放回队列,也可以直接忽略,放item自动掉落到传送带末端。当检测到pick传送带上没有item时,判断container中可以放置的下一个item和type,当有空位时,检测对应type的itme此时有没有重新在pick传送带上,如果有,则设置Picked=1,正常抓取,如果没有,判断一下buffer中有没有对应type的item,有则设置Picked=2,没有则设置Picked=0。

PROC PickPlaceSeq()

VAR num GQL:=0;

Picked:=0;

WHILE Picked=0 DO

IType:=0;

!=== PickPosAvailable ? ===

GQL:=GetQueueLevel(ItmSrcData{PickWorkArea{1}}.ItemSource\MinLimit:=InFlowEnter\MaxLimit:=InFlowExit);

If GQL>0 THEN

NextItmTgtType ItmSrcData{PickWorkArea{1}}.ItemSource,IType;

!=== Matching Item on outfeeder ? ===

GQL:=GetQueueLevel(ItmSrcData{PlaceWorkArea{1}}.ItemSource\ItmType:=IType\MinLimit:=OutFlowEnter\MaxLimit:=OutFlowExit);

IF GQL>0 THEN

Picked:=1;

ELSE

!=== Empty pos in buffer? ===

IF BufferIndex{IType}<BufferMax{IType} THEN

Picked:=3;

ELSE

!=== What to do with the item on the infeeder? ===

GetItmTgt ItmSrcData{PickWorkArea{1}}.ItemSource,PickTarget\ItemType:=IType;

TEST DropAction

CASE 0:

AckItmTgt ItmSrcData{PickWorkArea{1}}.ItemSource,PickTarget,TRUE;

CASE 1:

AckItmTgt ItmSrcData{PickWorkArea{1}}.ItemSource,PickTarget,FALSE;

CASE 2:

AckItmTgt ItmSrcData{PickWorkArea{1}}.ItemSource,PickTarget,FALSE\Skip:=TRUE;

ENDTEST

Picked:=0;

ENDIF

ENDIF

ELSE

GQL:=GetQueueLevel(ItmSrcData{PlaceWorkArea{1}}.ItemSource\MinLimit:=OutFlowEnter\MaxLimit:=OutFlowExit);

If GQL>0 THEN

NextItmTgtType ItmSrcData{PlaceWorkArea{1}}.ItemSource,IType;

!=== Matching Item on Infeeder ? ===

GQL:=GetQueueLevel(ItmSrcData{PickWorkArea{1}}.ItemSource\ItmType:=IType\MinLimit:=InFlowEnter\MaxLimit:=InFlowExit);

IF GQL>0 THEN

Picked:=1;

ELSE

!=== Matching pos in buffer? ===

IF BufferIndex{IType}>0 THEN

Picked:=2;

ELSE

Picked:=0;

ENDIF

ENDIF

ELSE

Picked:=0;

ENDIF

ENDIF

TEST Picked

CASE 0:

!=== No pick, no place ===

WaitTime 0.1;

CASE 1:

!=== pick infeed, place outfeed ===

Pick PickWorkArea{1},IType;

Place PlaceWorkArea{1},IType;

CASE 2:

!=== pick buffer, place outfeed ===

PickBuffer PickWorkArea{1},IType;

Place PlaceWorkArea{1},IType;

CASE 3:

!=== pick infeed, place buffer ===

Pick PickWorkArea{1},IType;

PlaceBuffer PlaceWorkArea{1},IType;

ENDTEST

ENDWHILE

ENDPROC

抓取item到buffer中

PROC PickBuffer(num Index,num TypeNr)

VAR num zboffs;

BufferX{TypeNr}:=(BufferIndex{TypeNr}-1)*BufferPitch{TypeNr};

WObjPick:=Wobj0;

zboffs:=BufferZ{TypeNr};

TriggL\Conc,Offs(RelTool(BufferPos{TypeNr},0,0,-ItmSrcData{Index}.OffsZ),BufferX{TypeNr},0,0),MaxSpeed,ItmSrcData{Index}.VacuumAct1,z20,PickAct1\WObj:=WObjPick;

TriggL\Conc,Offs(BufferPos{TypeNr},BufferX{TypeNr},0,zboffs),LowSpeed,ItmSrcData{Index}.SimAttach1,z5\Inpos:=ItmSrcData{Index}.TrackPoint,PickAct1\WObj:=WObjPick;

GripLoad ItemLoad;

MoveL Offs(RelTool(BufferPos{TypeNr},0,0,-ItmSrcData{Index}.OffsZ),BufferX{TypeNr},0,0),LowSpeed,z20,PickAct1\WObj:=WObjPick;

Decr BufferIndex{TypeNr};

ENDPROC

PROC PlaceBuffer(num Index,num TypeNr)

VAR num zboffs;

Incr BufferIndex{TypeNr};

BufferX{TypeNr}:=(BufferIndex{TypeNr}-1)*BufferPitch{TypeNr};

WObjPlace:=Wobj0;

zboffs:=BufferZ{TypeNr};

MoveL\Conc,Offs(RelTool(BufferPos{TypeNr},0,0,-ItmSrcData{Index}.OffsZ),BufferX{TypeNr},0,0),MaxSpeed,z20,PickAct1\WObj:=WObjPlace;

TriggL\Conc,Offs(BufferPos{TypeNr},BufferX{TypeNr},0,zboffs),LowSpeed,ItmSrcData{Index}.VacuumRev1\T2:=ItmSrcData{Index}.VacuumOff1\T3:=ItmSrcData{Index}.SimDetach1,z5\Inpos:=ItmSrcData{Index}.TrackPoint,PickAct1\WObj:=WObjPlace;

GripLoad load0;

MoveL Offs(RelTool(BufferPos{TypeNr},0,0,-ItmSrcData{Index}.OffsZ),BufferX{TypeNr},0,0),LowSpeed,z20,PickAct1\WObj:=WObjPlace;

ENDPROC

变量

- BufferMax,存储中item的最大缓存数量,数组元素的个数对应着item的type数量,程序中设置的是一个3个元素的数组,所以支持三种type的item,每个item允许最大缓存3个。

- BufferIndex,每个type的item当前在buffer中的数量

- BufferPitch,每个type的item每次在缓存Buffer区域中,X轴的偏移量

- BufferX,通过BufferPitch和BufferPitch计算的下一个item在buffer中的X坐标

- BufferZ,每个type的item在buffer中的高度

-

BufferPos,每个type的item在buffer中的第一个item的位置。

!*********************************************************** ! Global BUFFER Variables ! Robtarget BufferPos must be defined in wobj0 !*********************************************************** TASK PERS robtarget BufferPos{3}:=[ [[-200,-10,-1084],[0,-1,0,0],[0,0,0,0],[0,0,0,0,0,0]] , [[0,-10,-1084],[0,-1,0,0],[0,0,0,0],[0,0,0,0,0,0]] , [[200,-10,-1084],[0,-1,0,0],[0,0,0,0],[0,0,0,0,0,0]] ]; VAR num BufferMax{3}:=[4,4,4]; !Number of items i a buffer VAR num BufferPitch{3}:=[50,50,50]; !distance between buffer positions VAR num DropAction:=0; !What to do if an item can not be used. 0=Ack 1=Nack 2=Skip VAR num BufferZ{3}:=[0,0,0]; !Buffer Z-adjustments VAR num InFlowEnter:=-250; !Set to same as pickarea Enter limit VAR num InFlowExit:=250; !Set to litte before pickarea Exit limit VAR num OutFlowEnter:=-250; !Set to same as placearea Enter limit VAR num OutFlowExit:=250; !Set to litte before placearea Exit limit VAR num BufferX{3}; VAR num BufferY{3}; VAR num BufferIndex{3}:=[0,0,0]; VAR num IType:=0; VAR num Picked:=0;

确认PickType和PlaceType是否一致

!***********************************************************

!

! Procedure PickPlaceSeq

!

! The Pick and Place sequence.

! Edit this routine to modify from which work areas to pick and place.

! Needs to be changed if more than one pick work area is used.

! Needs to be changed if more than one place work area is used.

!

!***********************************************************

PROC PickPlaceSeq()

VAR num PickType:=1;

VAR num PlaceType:=1;

NextItmTgtType ItmSrcData{PlaceWorkArea{1}}.ItemSource,PlaceType;

PickType:=PlaceType;

TEST PickType

CASE 0:

Pick PickWorkArea{1};

CASE 2:

Pick PickWorkArea{2};

CASE 4:

Pick PickWorkArea{3};

DEFAULT:

ENDTEST

! NextItmTgtType ItmSrcData{PlaceWorkArea{1}}.ItemSource,PlaceType;

! Logging "NextType: PickType="+ValToStr(PickType)+", PlaceType="+ValToStr(PlaceType)+" "+ValToStr(PickType=PlaceType);

! WHILE PickType<>PlaceType DO

! GetItmTgt ItmSrcData{PlaceWorkArea{1}}.ItemSource,PlaceTarget;

! AckItmTgt ItmSrcData{PlaceWorkArea{1}}.ItemSource,PlaceTarget,TRUE;

! NextItmTgtType ItmSrcData{PlaceWorkArea{1}}.ItemSource,PlaceType;

! Logging "NextType: PickType="+ValToStr(PickType)+", PlaceType="+ValToStr(PlaceType)+" "+ValToStr(PickType=PlaceType);

! ENDWHILE

Place PlaceWorkArea{1};

ENDPROC

!***********************************************************

!

! Procedure Pick

!

! Executes a pick movement.

! Edit this routine to modify how the robot shall

! execute the pick movements.

! Needs to be changed if more than one activator is used.

!

!***********************************************************

PROC Pick(num Index)

IF Index>0 THEN

WObjPick:=ItmSrcData{Index}.Wobj;

GetItmTgt ItmSrcData{Index}.ItemSource,PickTarget;

Logging "Pick: PickType="+ValToStr(PickTarget.Type);

TriggL\Conc,RelTool(PickTarget.RobTgt,0,0,-ItmSrcData{Index}.OffsZ),MaxSpeed,ItmSrcData{Index}.VacuumAct1,z20,PickAct1\WObj:=WObjPick;

TriggL\Conc,PickTarget.RobTgt,LowSpeed,ItmSrcData{Index}.SimAttach1,z5\Inpos:=ItmSrcData{Index}.TrackPoint,PickAct1\WObj:=WObjPick;

GripLoad ItemLoad;

TriggL RelTool(PickTarget.RobTgt,0,0,-ItmSrcData{Index}.OffsZ),LowSpeed,ItmSrcData{Index}.Ack,z20,PickAct1\WObj:=WObjPick;

ELSE

ErrWrite "Missing item distribution","Cannot pick because no item distribution contains current work area."\RL2:="Please check configuration";

SafeStop;

ENDIF

ENDPROC

!***********************************************************

!

! Procedure Place

!

! Executes a place movement.

! Edit this routine to modify how the robot shall

! execute the place movements.

! Needs to be changed if more than one activator is used.

!

!***********************************************************

PROC Place(num Index)

IF Index>0 THEN

WObjPlace:=ItmSrcData{Index}.Wobj;

GetItmTgt ItmSrcData{Index}.ItemSource,PlaceTarget;

Logging "Place: PickType="+ValToStr(PickTarget.Type)+", PlaceType="+ValToStr(PlaceTarget.Type)+" "+ValToStr(PickTarget.Type=PlaceTarget.Type);

WHILE PickTarget.Type<>PlaceTarget.Type DO

AckItmTgt ItmSrcData{PlaceWorkArea{1}}.ItemSource,PlaceTarget,TRUE;

GetItmTgt ItmSrcData{Index}.ItemSource,PlaceTarget;

Logging "Place: PickType="+ValToStr(PickTarget.Type)+", PlaceType="+ValToStr(PlaceTarget.Type)+" "+ValToStr(PickTarget.Type=PlaceTarget.Type);

ENDWHILE

Logging "Place: PickType="+ValToStr(PickTarget.Type)+", PlaceType="+ValToStr(PlaceTarget.Type);

MoveL\Conc,RelTool(PlaceTarget.RobTgt,0,0,-ItmSrcData{Index}.OffsZ),MaxSpeed,z20,PickAct1\WObj:=WObjPlace;

TriggL\Conc,PlaceTarget.RobTgt,LowSpeed,ItmSrcData{Index}.VacuumRev1\T2:=ItmSrcData{Index}.VacuumOff1\T3:=ItmSrcData{Index}.SimDetach1,z5\Inpos:=ItmSrcData{Index}.TrackPoint,PickAct1\WObj:=WObjPlace;

GripLoad load0;

TriggL RelTool(PlaceTarget.RobTgt,0,0,-ItmSrcData{Index}.OffsZ),LowSpeed,ItmSrcData{Index}.Ack,z20,PickAct1\WObj:=WObjPlace;

ELSE

ErrWrite "Missing item distribution","Cannot place because no item distribution contains current work area."\RL2:="Please check configuration";

SafeStop;

ENDIF

ENDPROC

3进1出

FUNC bool IsPickPlaceMatched(num PickIndex,num PlaceIndex)

VAR bool PickPlaceMatched:=FALSE;

VAR num PickType:=1;

VAR num PlaceType:=1;

VAR num WaitTime:=1;

VAR bool TimeOutPick:=TRUE;

VAR bool TimeOutPlace:=TRUE;

Logging "Trying to match PickIndex="+ValToStr(PickIndex)+", PlaceIndex="+ValToStr(PlaceIndex)+" ...";

NextItmTgtType ItmSrcData{PickIndex}.ItemSource,PickType\MaxTime:=WaitTime/2\TimeFlag:=TimeOutPick;

NextItmTgtType ItmSrcData{PlaceIndex}.ItemSource,PlaceType\MaxTime:=WaitTime/2\TimeFlag:=TimeOutPlace;

IF TimeOutPick=FALSE AND TimeOutPlace=TRUE THEN

Logging "PickType="+ValToStr(PickType)+", but no container";

ELSEIF TimeOutPick=TRUE AND TimeOutPlace=FALSE THEN

Logging "PlaceType="+ValToStr(PlaceType)+", but no item";

ELSEIF TimeOutPick=FALSE AND TimeOutPlace=FALSE THEN

IF PickType=PlaceType THEN

PickPlaceMatched:=TRUE;

Logging "PickType=PlaceType="+ValToStr(PickType);

ELSE

Logging "PickType="+ValToStr(PickType)+", PlaceType="+ValToStr(PlaceType);

ENDIF

ENDIF

RETURN PickPlaceMatched;

ENDFUNC

!***********************************************************

!

! Procedure PickPlaceSeq

!

! The Pick and Place sequence.

! Edit this routine to modify from which work areas to pick and place.

! Needs to be changed if more than one pick work area is used.

! Needs to be changed if more than one place work area is used.

!

!***********************************************************

PROC PickPlaceSeq()

VAR num PickType:=1;

VAR num PlaceType:=1;

VAR num WaitTime:=1;

VAR bool TimeOutPick:=TRUE;

VAR bool TimeOutPlace:=TRUE;

VAR num PickIndex:=0;

IF IsPickPlaceMatched(PickWorkArea{1},PlaceWorkArea{1}) THEN

PickIndex:=1;

ELSE

IF IsPickPlaceMatched(PickWorkArea{2},PlaceWorkArea{1}) THEN

PickIndex:=2;

ELSE

IF IsPickPlaceMatched(PickWorkArea{3},PlaceWorkArea{1}) THEN

PickIndex:=3;

ENDIF

ENDIF

ENDIF

IF PickIndex>0 THEN

Pick PickWorkArea{PickIndex};

Place PlaceWorkArea{1};

ENDIF

ENDPROC

!***********************************************************

!

! Procedure Pick

!

! Executes a pick movement.

! Edit this routine to modify how the robot shall

! execute the pick movements.

! Needs to be changed if more than one activator is used.

!

!***********************************************************

PROC Pick(num Index)

VAR num PickType:=1;

VAR num PlaceType:=1;

VAR bool PickPlaceMatched:=FALSE;

IF Index>0 THEN

WObjPick:=ItmSrcData{Index}.Wobj;

WHILE NOT PickPlaceMatched DO

GetItmTgt ItmSrcData{Index}.ItemSource,PickTarget;

NextItmTgtType ItmSrcData{PlaceWorkArea{1}}.ItemSource,PlaceType;

PickPlaceMatched:=PickTarget.Type=PlaceType;

Logging "Pick "+ValToStr(Index)+" : PickType="+ValToStr(PickTarget.Type)+", PlaceType="+ValToStr(PlaceType)+" "+ValToStr(PickPlaceMatched);

IF NOT PickPlaceMatched THEN

AckItmTgt ItmSrcData{Index}.ItemSource,PickTarget,FALSE\Skip:=TRUE;

ENDIF

ENDWHILE

TriggL\Conc,RelTool(PickTarget.RobTgt,0,0,-ItmSrcData{Index}.OffsZ),MaxSpeed,ItmSrcData{Index}.VacuumAct1,z20,PickAct1\WObj:=WObjPick;

TriggL\Conc,PickTarget.RobTgt,LowSpeed,ItmSrcData{Index}.SimAttach1,z5\Inpos:=ItmSrcData{Index}.TrackPoint,PickAct1\WObj:=WObjPick;

GripLoad ItemLoad;

TriggL RelTool(PickTarget.RobTgt,0,0,-ItmSrcData{Index}.OffsZ),LowSpeed,ItmSrcData{Index}.Ack,z20,PickAct1\WObj:=WObjPick;

ELSE

ErrWrite "Missing item distribution","Cannot pick because no item distribution contains current work area."\RL2:="Please check configuration";

SafeStop;

ENDIF

ENDPROC

!***********************************************************

!

! Procedure Place

!

! Executes a place movement.

! Edit this routine to modify how the robot shall

! execute the place movements.

! Needs to be changed if more than one activator is used.

!

!***********************************************************

PROC Place(num Index)

VAR bool PickPlaceMatched:=FALSE;

IF Index>0 THEN

WObjPlace:=ItmSrcData{Index}.Wobj;

WHILE NOT PickPlaceMatched DO

GetItmTgt ItmSrcData{Index}.ItemSource,PlaceTarget;

PickPlaceMatched:=PickTarget.Type=PlaceTarget.Type;

Logging "Place "+ValToStr(Index)+" : PickType="+ValToStr(PickTarget.Type)+", PlaceType="+ValToStr(PlaceTarget.Type)+" "+ValToStr(PickPlaceMatched);

IF NOT PickPlaceMatched THEN

AckItmTgt ItmSrcData{Index}.ItemSource,PlaceTarget,FALSE\Skip:=TRUE;

ENDIF

ENDWHILE

MoveL\Conc,RelTool(PlaceTarget.RobTgt,0,0,-ItmSrcData{Index}.OffsZ),MaxSpeed,z20,PickAct1\WObj:=WObjPlace;

TriggL\Conc,PlaceTarget.RobTgt,LowSpeed,ItmSrcData{Index}.VacuumRev1\T2:=ItmSrcData{Index}.VacuumOff1\T3:=ItmSrcData{Index}.SimDetach1,z5\Inpos:=ItmSrcData{Index}.TrackPoint,PickAct1\WObj:=WObjPlace;

GripLoad load0;

TriggL RelTool(PlaceTarget.RobTgt,0,0,-ItmSrcData{Index}.OffsZ),LowSpeed,ItmSrcData{Index}.Ack,z20,PickAct1\WObj:=WObjPlace;

ELSE

ErrWrite "Missing item distribution","Cannot place because no item distribution contains current work area."\RL2:="Please check configuration";

SafeStop;

ENDIF

ENDPROC

多个传送带Item,一个Container传送带

当多个item放到一个container时,为了避免错放,需要添加GetItmTgt指令的ItemType参数。GetItmTgt ItmSrcData{Index}.ItemSource,PlaceTarget\ItemType:=PickTarget.Type;

PROC PickPlaceSeq()

VAR num PickType:=1;

VAR num PlaceType:=1;

VAR num WaitTime:=1;

VAR bool TimeOutPick:=TRUE;

VAR bool TimeOutPlace:=TRUE;

VAR num PickIndex:=0;

NextItmTgtType ItmSrcData{PlaceWorkArea{1}}.ItemSource,PlaceType;

PickType:=PlaceType;

TEST PickType

CASE 0:

Pick PickWorkArea{1};

CASE 2:

Pick PickWorkArea{2};

CASE 4:

Pick PickWorkArea{3};

DEFAULT:

ENDTEST

Place PlaceWorkArea{1};

ENDPROC

!***********************************************************

!

! Procedure Pick

!

! Executes a pick movement.

! Edit this routine to modify how the robot shall

! execute the pick movements.

! Needs to be changed if more than one activator is used.

!

!***********************************************************

PROC Pick(num Index)

VAR num PickType:=1;

VAR num PlaceType:=1;

VAR bool PickPlaceMatched:=FALSE;

IF Index>0 THEN

WObjPick:=ItmSrcData{Index}.Wobj;

GetItmTgt ItmSrcData{Index}.ItemSource,PickTarget;

TriggL\Conc,RelTool(PickTarget.RobTgt,0,0,-ItmSrcData{Index}.OffsZ),MaxSpeed,ItmSrcData{Index}.VacuumAct1,z20,PickAct1\WObj:=WObjPick;

TriggL\Conc,PickTarget.RobTgt,LowSpeed,ItmSrcData{Index}.SimAttach1,z5\Inpos:=ItmSrcData{Index}.TrackPoint,PickAct1\WObj:=WObjPick;

GripLoad ItemLoad;

TriggL RelTool(PickTarget.RobTgt,0,0,-ItmSrcData{Index}.OffsZ),LowSpeed,ItmSrcData{Index}.Ack,z20,PickAct1\WObj:=WObjPick;

ELSE

ErrWrite "Missing item distribution","Cannot pick because no item distribution contains current work area."\RL2:="Please check configuration";

SafeStop;

ENDIF

ENDPROC

!***********************************************************

!

! Procedure Place

!

! Executes a place movement.

! Edit this routine to modify how the robot shall

! execute the place movements.

! Needs to be changed if more than one activator is used.

!

!***********************************************************

PROC Place(num Index)

VAR bool PickPlaceMatched:=FALSE;

IF Index>0 THEN

WObjPlace:=ItmSrcData{Index}.Wobj;

GetItmTgt ItmSrcData{Index}.ItemSource,PlaceTarget\ItemType:=PickTarget.Type;

MoveL\Conc,RelTool(PlaceTarget.RobTgt,0,0,-ItmSrcData{Index}.OffsZ),MaxSpeed,z20,PickAct1\WObj:=WObjPlace;

TriggL\Conc,PlaceTarget.RobTgt,LowSpeed,ItmSrcData{Index}.VacuumRev1\T2:=ItmSrcData{Index}.VacuumOff1\T3:=ItmSrcData{Index}.SimDetach1,z5\Inpos:=ItmSrcData{Index}.TrackPoint,PickAct1\WObj:=WObjPlace;

GripLoad load0;

TriggL RelTool(PlaceTarget.RobTgt,0,0,-ItmSrcData{Index}.OffsZ),LowSpeed,ItmSrcData{Index}.Ack,z20,PickAct1\WObj:=WObjPlace;

ELSE

ErrWrite "Missing item distribution","Cannot place because no item distribution contains current work area."\RL2:="Please check configuration";

SafeStop;

ENDIF

ENDPROC